Polyester fabric is a cost effective alternative to nylon fabric for bicycle bags. While it is not quite as durable and lightweight as nylon, its lower cost can make it an excellent option for many bike bag applications. Additionally, polyester is inherently more water-resistant than nylon and dries faster than nylon, making it advantageous in bicycle bags designed for frequent use in wet conditions. It often receives additional coatings to boost its waterproof qualities. A notable example is Ortlieb’s “Classic” bag material which is a PVC coated polyester.

A Brief History of Polyester Fabrics in Bike Bags

Polyester, was first developed in the early 20th century and patented as Terylene by British chemists Whinfield and Dickson, gained recognition in the 1940s when DuPont began U.S. production under the name Dacron. Its popularity soared in the 1960s and 1970s in the fashion industry due to its durability and low maintenance, though it later declined due to its association with fashion excess and a shift toward natural fibers. Recently, polyester has experienced a resurgence, especially in outdoor and performance wear, due to the development of recycled polyester, aligning with enhanced environmental sustainability efforts.

- 1970s-1980s: As recreational cycling and bike touring gain popularity, manufacturers begin using polyester in the production of bike bags due to its lightweight, durability, and ease of maintenance.

- 1990s: Advances in textile technology lead to the development of more sophisticated polyester materials, including ripstop and multi-layered fabrics, enhancing durability and weather resistance.

- 2000s: The cycling industry sees a shift towards specialized cycling activities like bikepacking, which demands even more from gear. Polyester fabrics are engineered with improved water and UV resistance to meet these needs.

- 2010s: With growing environmental awareness, the cycling industry starts incorporating recycled polyester into bike bags, significantly reducing the environmental impact while maintaining functionality.

- 2020s: The trend towards sustainability continues, with even greater use of recycled polyester and ongoing innovations in fabric treatments to enhance the performance and durability of bike bags.

Bike Bag Friendly Properties of Polyester Fabrics

Polyester offers a balanced combination of durability, structural integrity, environmental resistance, and cost-effectiveness, making it a solid choice for bike bags used in various cycling conditions. Its easy maintenance and lightweight nature also add to its appeal for the active cyclist.

- Durability: Polyester is highly durable and resistant to stretching and shrinking, which makes it ideal for the rigorous demands of bikepacking. It withstands repeated use and exposure to stresses without losing its integrity, thus ensuring longevity for the bag.

- Structure: The fabric maintains its shape well and can be designed to offer varying degrees of stiffness depending on the weaving or processing method used. This structural integrity helps keep bike bags stable and secure, even when packed with gear.

- Water Resistance: Polyester inherently resists water penetration to a degree, but most polyester bags also undergo special treatments or coatings (like PVC or TPU) to enhance their water resistance. This makes them suitable for use in different weather conditions, protecting contents from rain and road spray.

- Environmental Resistance: Beyond just water, polyester is resistant to many environmental factors including UV rays and mildew. This resistance helps prevent the degradation of the fabric when exposed to sunlight for prolonged periods or in damp conditions, thus preserving the bag’s functional and aesthetic qualities.

- Maintenance: Polyester is easy to clean and dries quickly, which is particularly useful for bicycle travel where bags may get muddy or dirty. Typically, cleaning involves just wiping down or washing with soap and water, and the fabric’s resistance to stains means it keeps looking good with minimal effort.

- Weight: The fabric is relatively lightweight, which is crucial for biking applications where added weight can impact handling and efficiency. Polyester bags contribute minimally to the overall load, helping to maintain ease of movement and balance.

- Cost: Polyester is generally less expensive than some other high-performance fabrics like nylon. This cost-effectiveness makes polyester bags a popular choice among cyclists who seek durability and functionality without a high price tag.

Polyester Fabric Sub-Types & Their Usage in Bicycle Bags

PVC Coated Polyester

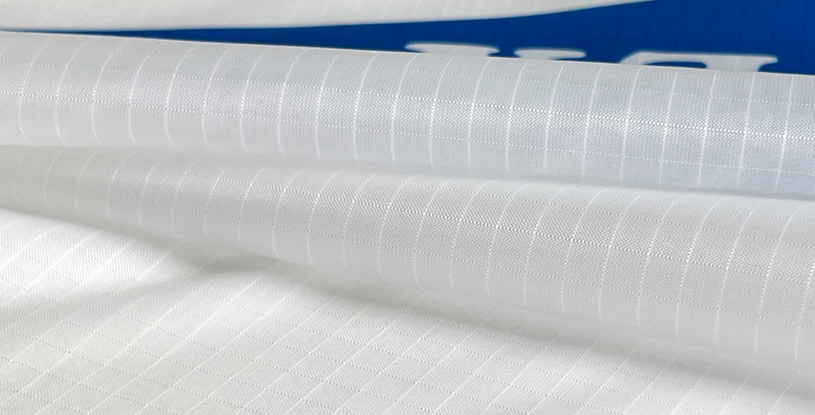

PVC-coated polyester is a highly durable and waterproof fabric created by applying a layer of polyvinyl chloride (PVC) to polyester fabric. It is widely used for outdoor and industrial applications due to its excellent resistance to abrasion, weather, and chemicals.

Examples of Bike Bags at Campfire Utilizing PVC Coated Polyester

PU Coated Polyester

PU-coated polyester is a versatile fabric enhanced by applying a polyurethane coating to polyester fibers, boosting its water resistance and durability. This material is particularly valued for its flexibility and mildew resistance, making it suitable for outdoor gear, waterproof clothing, and various protective covers. The combination of polyester’s strength and PU’s protective properties creates a fabric ideal for environments where durability and weather resistance are essential.